Maple syrup operation up and running at Tosanak Recreation area

By Kelly Terpstra, kterpstra@charlescitypress.com

Nestled along a winding, muddy path at the Tosanak Recreation Area sits a small building where hoses are hooked up, gauges are read and logs are thrown into the fire.

Soon many area residents will be reaping the rewards of this delicate dance.

Pour the batter because cases of maple syrup will soon be available for those who love to slather the sweet goodness over warm breakfast pancakes or waffles.

The maple magic being cooked and bottled has been made possible by a local group headed by Floyd resident Bruce Bergland. Several students from Iowa BIG North have also volunteered their time and energy to help tap over 100 maple trees that sit on Tosanak property that will eventually produce dozens of gallons of maple syrup.

“On a good day we should be able to get 300 gallons of sap a day, maybe even more,” said Bergland.

Bergland and several other interested folks who know how to run the operation purchased the equipment, storage tanks and large 15-foot-wide evaporator that boils the sap into syrup, last fall.

“It’s pretty technical, it really is,” said Gene Rasmussen.

As the evaporator is fed logs to fuel the fire, clouds billow out of the building’s flue. The clear liquid sap is turning into the desired color of maple and the consistency of syrup.

“That’s steam that you see. You don’t even see the smoke because it’s burning so efficiently,” said Bergland.

Bergland and two crews collected about 150 gallons of sap the first day the trees were tapped last Saturday. Sunday wasn’t quite as good, he said, as only 80 gallons filled the metal buckets that hang around the trunk of the trees.

The ratio of sap to syrup is 40 to 1. So every 40 gallons of sap boiled down produces one gallon of syrup.

“Thirty-nine gallons is going out through the steam pipe,” said Craig Pogemiller, who has helped Bergland learn the skill of creating syrup and make sure every hose, nozzle and siphon is in working order and doing its job correctly.

“He is so handy. He pretty much figured out how to set all this up,” Bergland said about Pogemiller.

Bergland said early on in the tapping process that ratio of sap to syrup may fall to as low as 30-1 because the sap is more concentrated.

“For some reason the sap is sweeter,” he said.

Cold winter nights and cool days produce what is somewhat of a hydraulic process that runs the sap up and down the inside of the tree. The freeze helps circulate the sap and when it warms up the result is a constant drip of sugary nectar into a pail during peak season.

“The alternating freezing and thawing is what it needs,” said Bergland.

That peak season is now and could run throughout the month of March if the weather cooperates, Bergland said. The reduction in flow of sap usually takes place when the buds on trees start to swell and spring is ready to blossom.

“When the sap starts getting cloudy, we’re done,” Bergland said.

A temperature of 219-degrees fahrenheit needs to be maintained in the evaporator to produce the pancake pouring perfection.

“If it gets below that, it isn’t maple syrup. If it gets over – the thing burns. You get sugar,” said Rasmussen.

The resulting syrup is 100 percent maple syrup with no additives or preservatives.

“This is the real stuff,” said Bergland.

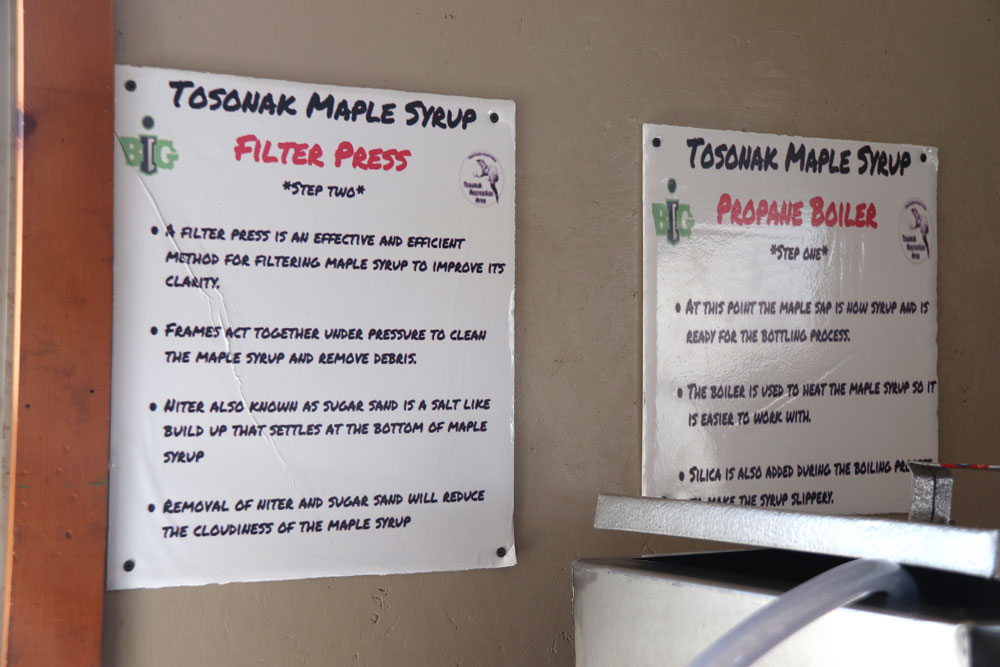

There is also a room just down the path from the evaporator building where the syrup is filtered and put into sterilized bottles. Tosanak Maple Syrup, as it will be called, will come in quart, pint and half-pint bottles. The logo on the front of the bottle will feature an otter. Tosanak is a Winnebago Indian term meaning “slippery one” and refers to the Otter River.

The group making the syrup has an old 300-gallon metal milk storage tank inside the building where the evaporator sits. There is a 500-gallon metal tank outside as well. An ATV is used to navigate the forested area and collect the sap near each tree. Bergland said half of the trees are north of the evaporator building and the other 50 or so trees sit due south. That liquid is then poured into the outside tank. A sump pump then transfers the sap inside to where it will be cooked and turned into syrup.

Bergland said the first batch of syrup will be given to those that helped donate to fund the operation. They will receive a quart of syrup for every $100 they contributed.

Bergland said the group has spent about $12,000 to get the operation up and running. Some of the proceeds will go toward paying off that debt but Bergland said all profit after that will go back to Floyd County Conservation and the Fossil and Prairie Conservation Foundation.

Bergland said that some of the syrup may be ready to be either sold or auctioned off at the Fossil and Prairie Conservation Foundation’s Spring Celebration Gala that will be held at the Youth Enrichment Center this Saturday evening.

“We’re working under their umbrella,” said Bergland.

Bergland said he has also partnered with some local businesses – Rustic Corner and Otto’s Oasis – that have said they are interested in selling some of the locally made product.

Bergland also said there will be an open house and pancake feed on Saturday, March 21, from 10 a.m. until 1 p.m. at the Director’s Lodge at Tosanak.

Social Share